Two Students Participate in Eight-Week Engineering Internship

Seniors Harrison Delecki and Sophia Rouman worked for Precision Gasket Company.

Edina High School seniors Harrison Delecki and Sophia Rouman recently participated in and completed an eight-week internship at Precision Gasket Company (PGC), thanks to the opportunity provided EHS Project Lead The Way teacher Jodi Ramirez. The two were given a specific task to complete for the internship.

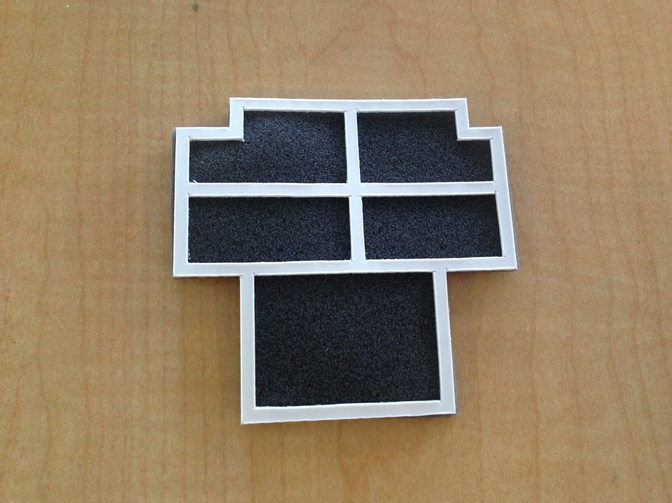

“For the internship project with PGC, the project objective was to design and develop a more efficient and less expensive air filter for the overhead projectors that would be used in the Edina district classrooms,” said Rouman. This task would require much attention to detail and hard work. “We spent the first two weeks learning as much as we could about everything that was available to us,” said Delecki.

With the tools of an engineering firm at hand, the internship was interesting and informative for Rouman and Delecki. “It was great to see things we learned how to do in school being applied in a business setting. The people that we worked with at PGC were great, they were always friendly and quick to offer help,” said Delecki.

In addition to the help they were given, being at PGC allowed them to observe engineers in their work environment. “I was able to work alongside engineers and see what kind of work they do everyday and what projects they work on,” said Rouman.

The nature of the project made the process a true test of their abilities as designers and engineers. “[We] started by taking measurements of the existing air filters in the projectors in order to know the specific dimensions the new filter would need to be. From there [we] researched various plastics, foams, and adhesives, and selected the optimal three materials in order to make the filters,” said Rouman.

The next step was design. “Once we narrowed down our selection of materials, we made prototypes, which were tested to make sure they didn’t melt or anything,” said Delecki.

The entire process of making projector filters from start to finish was a fulfilling experience for these two. “It is a great and rewarding feeling to see something you designed, developed and produced, being used and benefiting others,” said Rouman.

Despite their success, the process wasn’t all easy work. “I think the hardest part of the internship was the research, we had to learn a lot very quickly. Sophia and I didn’t know anything about plastics and adhesives going in to the internship,” said Delecki. For Rouman, “The hardest part was trying to meet necessary deadlines while creating the best product possible given the project constraints.”

The internship provided them invaluable knowledge on the profession of engineering, something they both wish to pursue in the future. “The internship with PGC confirmed my interest in mechanical engineering by providing me with hands-on experience with other engineers in a business setting,” said Rouman. “Understanding how many people in different roles work together on one project is going to help me immensely when I enter the job market after college,” said Delecki.

From the internship at PGC, these two students will take away a lot of important information and experience. “It was a great opportunity to apply my PLTW engineering class work to a real project in a business setting,” said Rouman.

Thanks to a special opportunity provided by Ms. Ramirez, these two students were able to accomplish an important task for the Edina Public School district and set an example of student innovation and dedication for students to come.

Noah Chestler isn’t your average joe, he’s a little bit better than mediocre, with an exceptional body. The claim is confirmed after taking a look...